Reduce food waste by improving process hygiene

Reducing food waste is an important socioeconomic goal that is connected to several of the UN's global goals. A number of Danish food companies have begun to tackle this issue.

As many participants pointed out during the first Food Waste Awareness Day, addressing the issue involves reducing waste during production and ensuring that as much as possible of the produced food is eaten, not thrown away. There have been many good suggestions on how to make this happen.

Hygiene in food manufacturing

Unfortunately, the topic of process hygiene was under-represented in the debate. Deficient process hygiene results in rather significant losses of manufactured food products.

The Danish Veterinary and Food Administration's list of food recalls speaks for itself. Among the entries on the list are products that were pulled from store shelves after they were found to be contaminated with yeast and mould.

If we also consider that businesses typically identify contaminated products before they become available to consumers, this adds up to a significant amount of waste. Insufficient hygiene in manufacturing is one cause of this waste, and this issue is often the result of lacking specifications and risk assessments for manufacturing processes.

Documentation and validation

We have encountered many cases in which food manufacturing companies struggled to prioritise and set aside sufficient time to validate new processes and perform thorough risk assessments for them. Needs may not be properly identified, documentation and validation plans may be outdated, and qualification processes may be skipped or "adapted" for the sake of convenience.

Unfortunately, improving hygiene in production tends not to be viewed as justification for the required investment. Instead, businesses focus on increasing capacity or minimising other costs. This is the reality that many food manufacturing businesses and equipment vendors alike operate in.

The solution is to incorporate hygienic operation into all projects that involve building new process facilities or manufacturing new projects using existing equipment. Good hygiene depends on equipment and process lines that are optimally designed from a hygienic standpoint, and getting that in place means doing the right preparatory work in terms of specifications.

This means spending more time in the design phase and perhaps choosing solutions that are more expensive—so yes, hygienic design is often a more expensive investment, but it tends to pay off in the long run. Reaching this conclusion requires total cost of ownership (TOC) calculations, but doing so is made more difficult by a lack of appropriate tools. This also requires changes from food manufacturing businesses, which must prioritise objective decision-making in hygienic design.

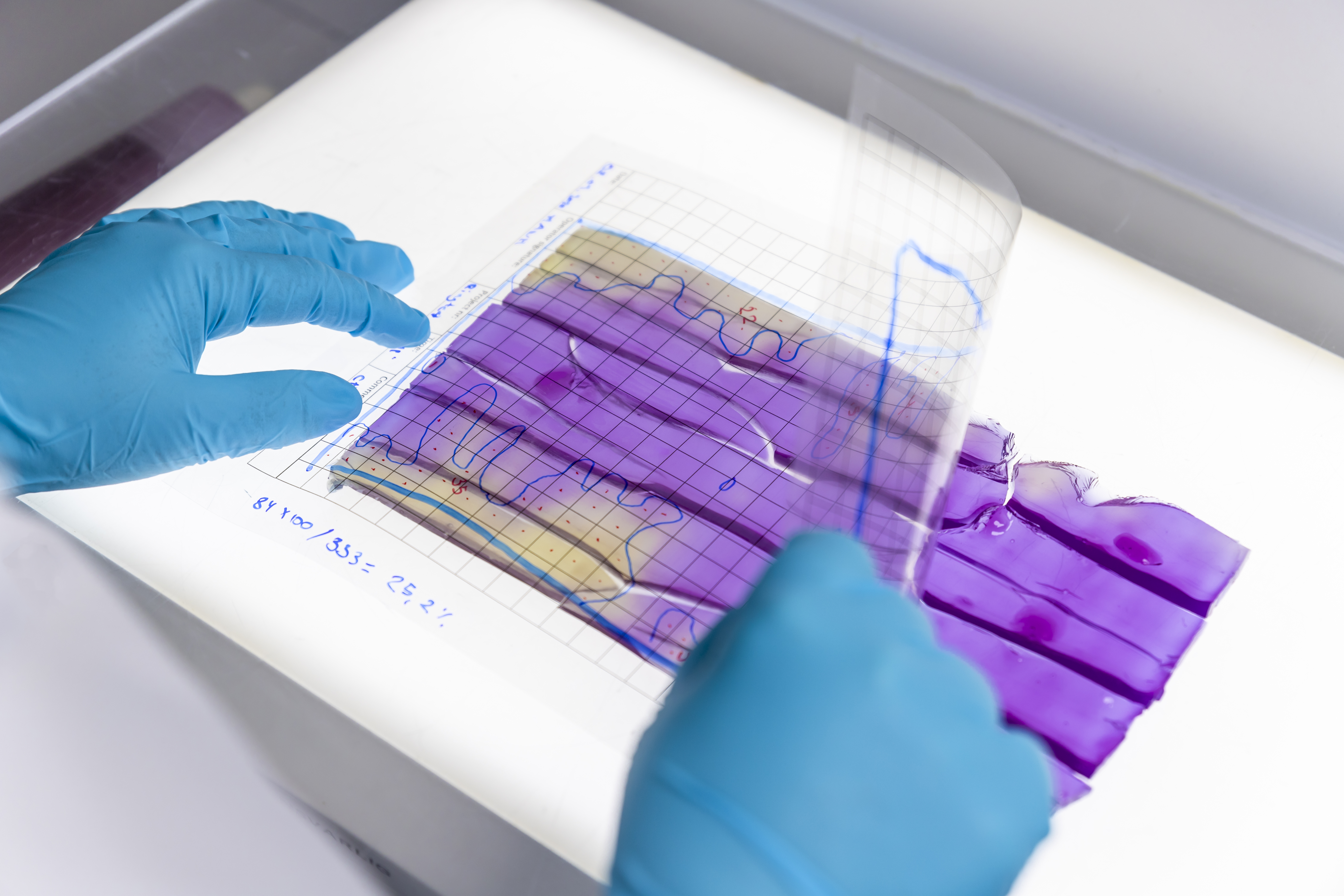

This is one of the areas in which FORCE Technology can support the industry. We handle everything from hygienic design assessment and cleanability testing to installation validation and cleanliness verification.