Profitability of retrofitting your vessel

Retrofit of existing ships is becoming increasingly interesting for shipowners. It provides the possibility to save fuel and stay competitive against newer eco-designs

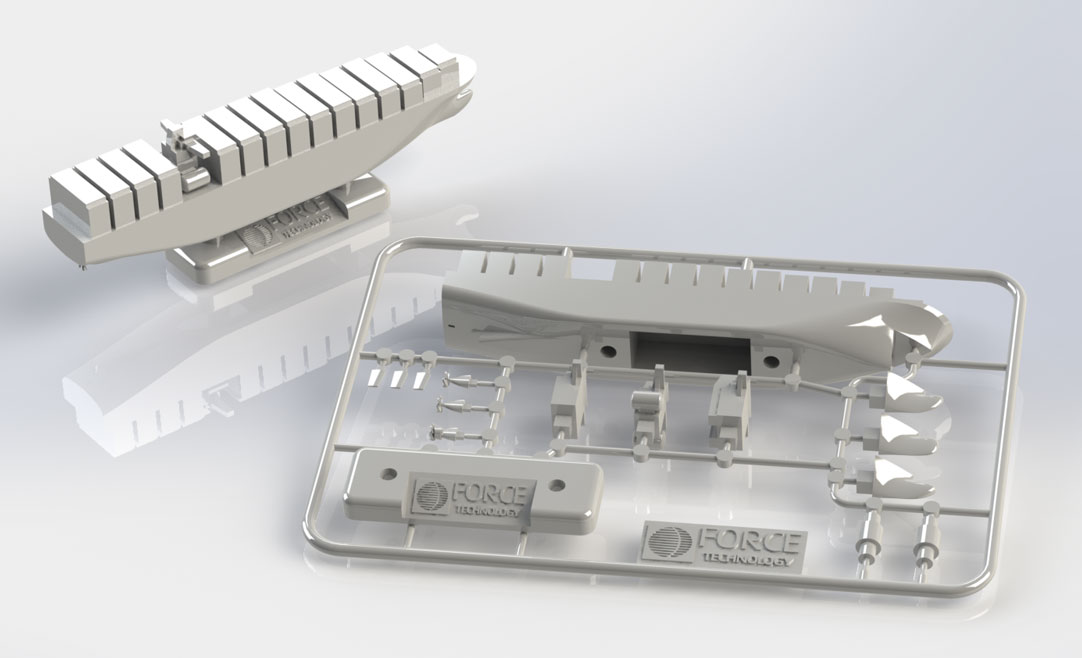

The challenge for the owners is to select the retrofit technology and compare different solutions on a fair baseline. FORCE Technology can assist the shipowner in this progress through our ‘ECOfit’-service. For each ship or class, the ECOfit starts with a technology screening looking at available sense-making solutions for the ship in question.

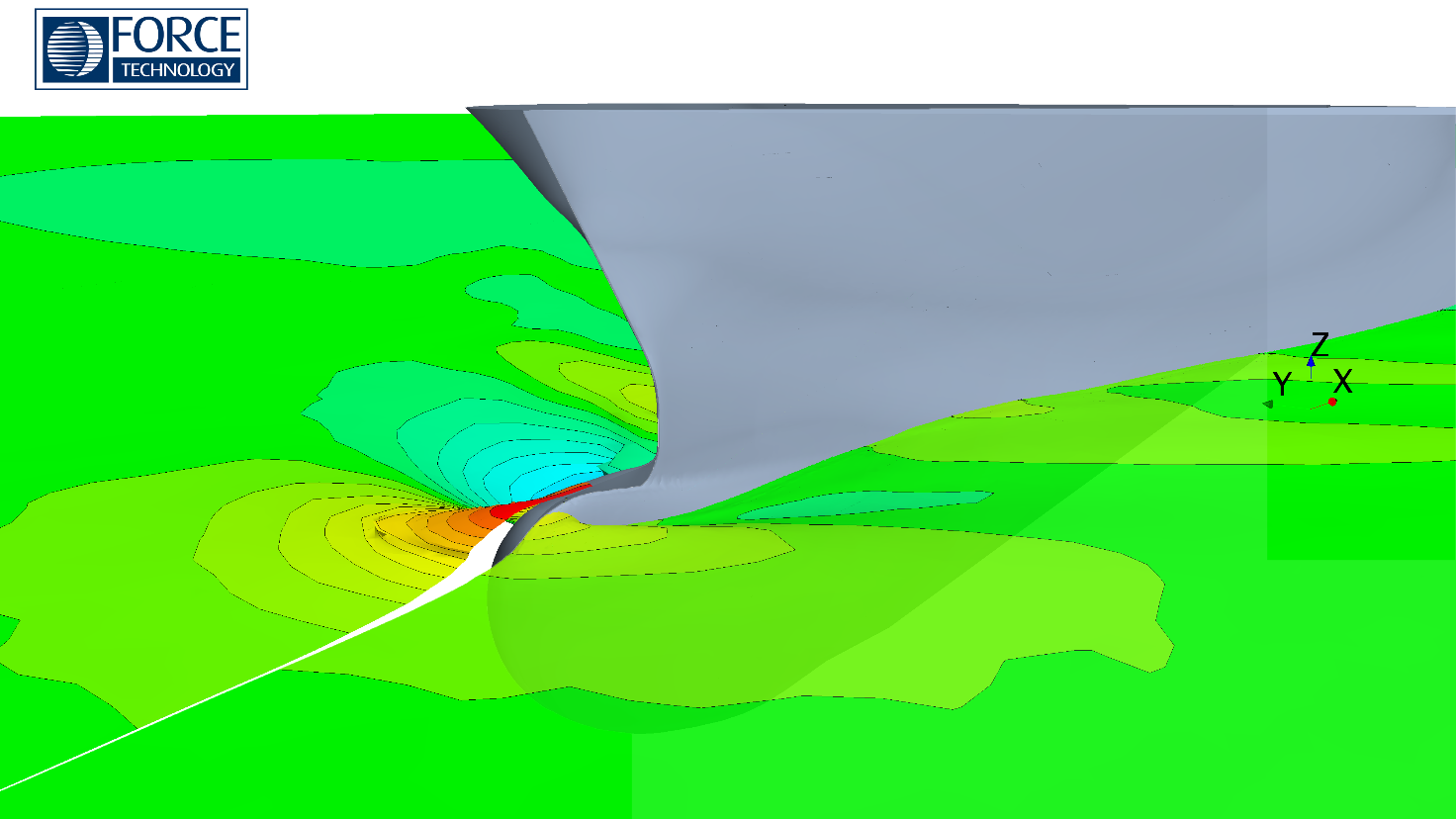

Most owners already have an idea about the problem, but through the ECOfit technology, the possible solutions can be compared on a fair baseline using our profound hydrodynamic experience, advanced CFD tools and our large database of performance data. Moreover, the different technologies are not only compared under ideal conditions but also at the actual operational profile of the vessel including actual time at sea, variation of draughts and speeds, etc.

The initial investment

An essential part of assessing the profitability of a retrofit is to know the size of the initial investment. This knowledge is obtained through dialogue with the shipowner as well as cooperation with leading naval architects, good connections with suppliers and our experience.

Retrofit technology testing

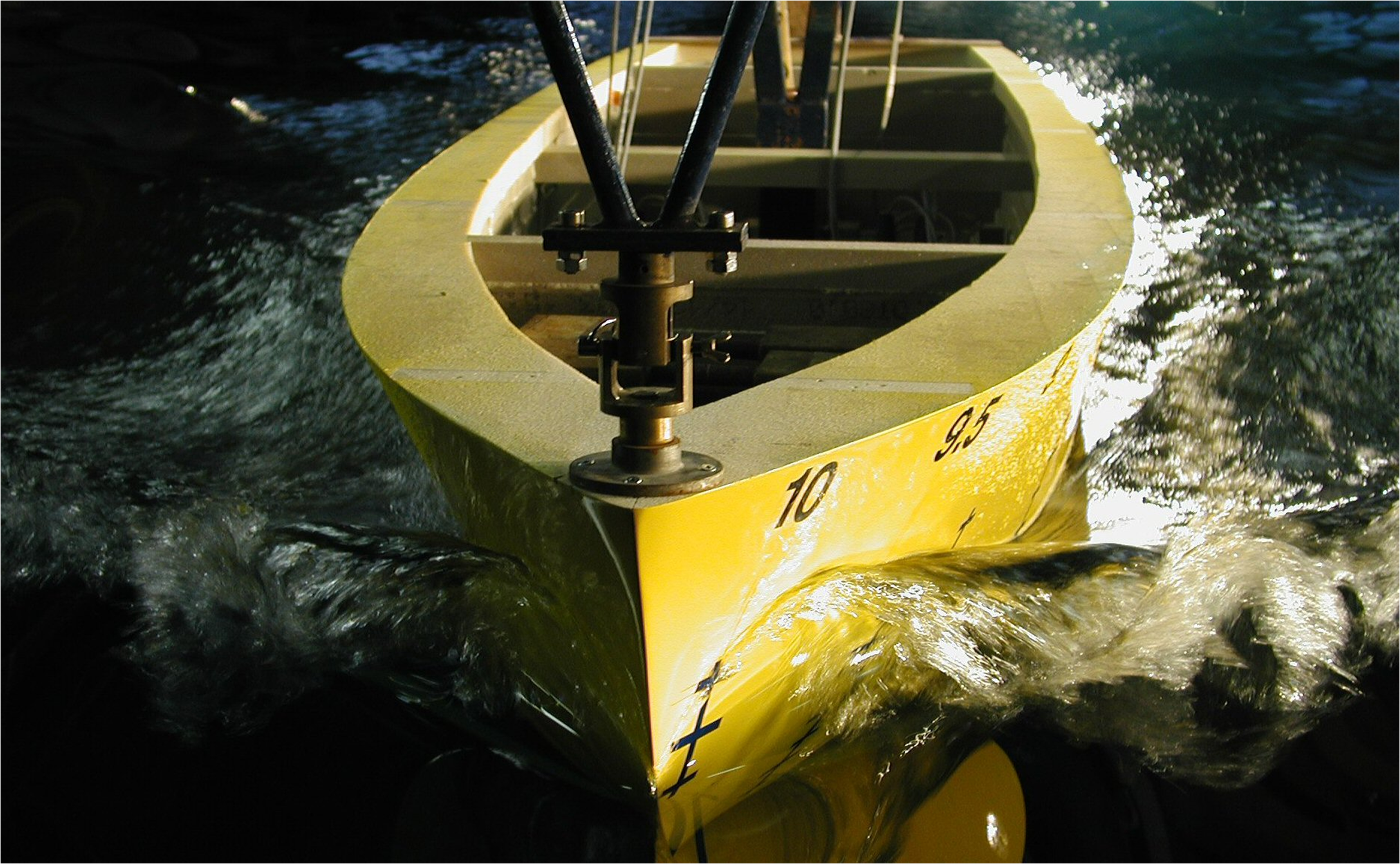

In order to find the accurate ROI for the retrofit, a detailed technology screening must be carried out to assess the power savings. If one of the selected technologies is to retrofit a new bulbous bow, a CFD design study will be performed and verified by towing tank testing on a range of draughts, trims and speeds in order to find the specific ROI.For a new propeller study, self-propulsion towing tank tests are performed with both the original ‘as-built’ propeller and the new propeller design. These tests are again performed at a range of speeds and draughts to provide input to the ROI calculation

Change of the operational profile

Generally, most retrofitting projects become interesting when the operational profile of the vessel is changed significantly from the original design point. In some cases, an attractive ROI is obtained by making radical hull form changes like retrofitting a bulbous bow.This, however, always requires a detailed study, and the ROI is highly dependent on the current and future operation of the vessel. In other cases, what appears to be large power savings in percentage for retrofitting a propeller might not be attractive if the ship super slow steams and does not burn much fuel, i.e. the reduction in operating cost obtained by the propeller retrofit is not significant enough to give a reasonable ROI.

This might be affected by commercial reasons if the future trend is increasing speed. Often it improves the ROI to consider more retrofit solutions in one conversion, creating retrofit packages as this distributes some of the fixed cost like docking, off-hire etc.

Looking at the portfolio of retrofit studies in which FORCE Technology has been involved, the ROI varies quite a lot for the individual ships. Securing the ROI may require detailed studies, but often it pays off.