Advanced real-time monitoring in supply chains

End-to-end transparency in the supply chain will increase the international competitiveness of Danish businesses.

Why advanced real-time monitoring in supply chains?

Smart sensors and sensor technology are known to facilitate transparency throughout the entire supply chain and serve as a basis for the growth of data-driven decision-making.However, studies mention the need for greater investments in new technologies, a lack of convincing business models, few internal competencies, and resistance to new technology as some of the reasons that Danish small- and medium-sized businesses have been reluctant to move toward a digital supply chain.

Purpose of the project

The purpose of the project is to create methods, tools and technologies that are to leverage the IoT transparency in supply chains. This will enable a translation from a traditional supply chain model – where companies generally interact with their direct suppliers and customers – to an integrated supply chain ecosystem, where a company is able to coordinate its activities according to the status of all its partners, thereby improving the overall performance.

Who will benefit from the project?

This project is focused on the following primary target groups:

- Food service sector: Primary producers, dairy businesses, processing businesses, fresh produce suppliers, agriculture, fruits/vegetables, etc.

- Component / semi-finished production businesses: Part suppliers for larger enterprises.

- Pharmaceutical and medical industry: Suppliers of hospital and clinic products; transport of fragile and sensitive goods.

Partners

The project is conducted in close co-operation with researchers within smart production from Aalborg University’s department of Materials and Production.

The aim is to develop and test tools and methods for uncovering the needs and potentials with implementing an IoT monitoring solution in a supply chain, based on the latest research in the area. These tools and methods aim to:

- Identify the key performance improvement opportunities.

- Design a tailored IoT solution for addressing the most relevant one.

- Evaluate - qualitatively and quantitatively – the impact of the solution.

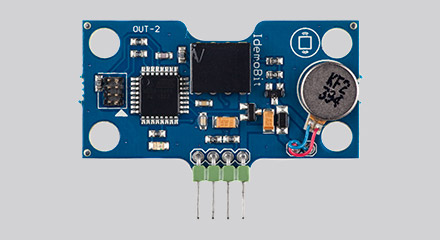

Development of examples and demonstration of technologies that can provide transparency in supply chains are developed in collaboration between FORCE Technology and Presto Engineering.

Related community work

Related services

Discovering for Industrial IoT potentials

Industrial IoT optimises performance and quality of the manufacturing and supply chain.

Optimising with industrial IoT

IoT in supply chains can optimise logistics - but also create new business opportunities.

IoT-based predictive maintenance

Customised IoT-based predictive maintenance concepts and solutions.