Drone inspection services

Drone inspection makes it possible to access areas that may pose health, safety and environmental risks in a fast and safe way.

Benefits of drone inspection

Using our drone inspection services for visual inspection, provide benefits such as:

- inspection of areas difficult to access

- preventive maintenance planning and optimised production

- access to areas that pose health, safety and environmental risk to humans

- quick on-site deployment of the drone inspection system

- authorised and qualified UAV-inspection personnel

- reduced downtime.

Where can we fly – what to inspect?

Click on the relevant area below and read more about our drone inspection solution.Drone inspection areas

Drone inspection of offshore oil and gas constructions

High resolution images and video of otherwise inaccessible areas of an offshore platform.

Drone inspection of power and hydro power plants

Get a safe and fast overview of the state of your plant - buildings, equipment and pipe systems.

Drone inspection of power lines and civil infrastructure

Quick overview and evaluation of the condition of bridges, power lines, buildings and rooftops.

Drone inspection of wind turbines – on- and offshore

Fast set up - Assessing the condition of the wind turbine with visual or thermographic images.

Drone inspection in the food industry

Get visual overview of a production site and carry out e.g. condition control and leakage detection.

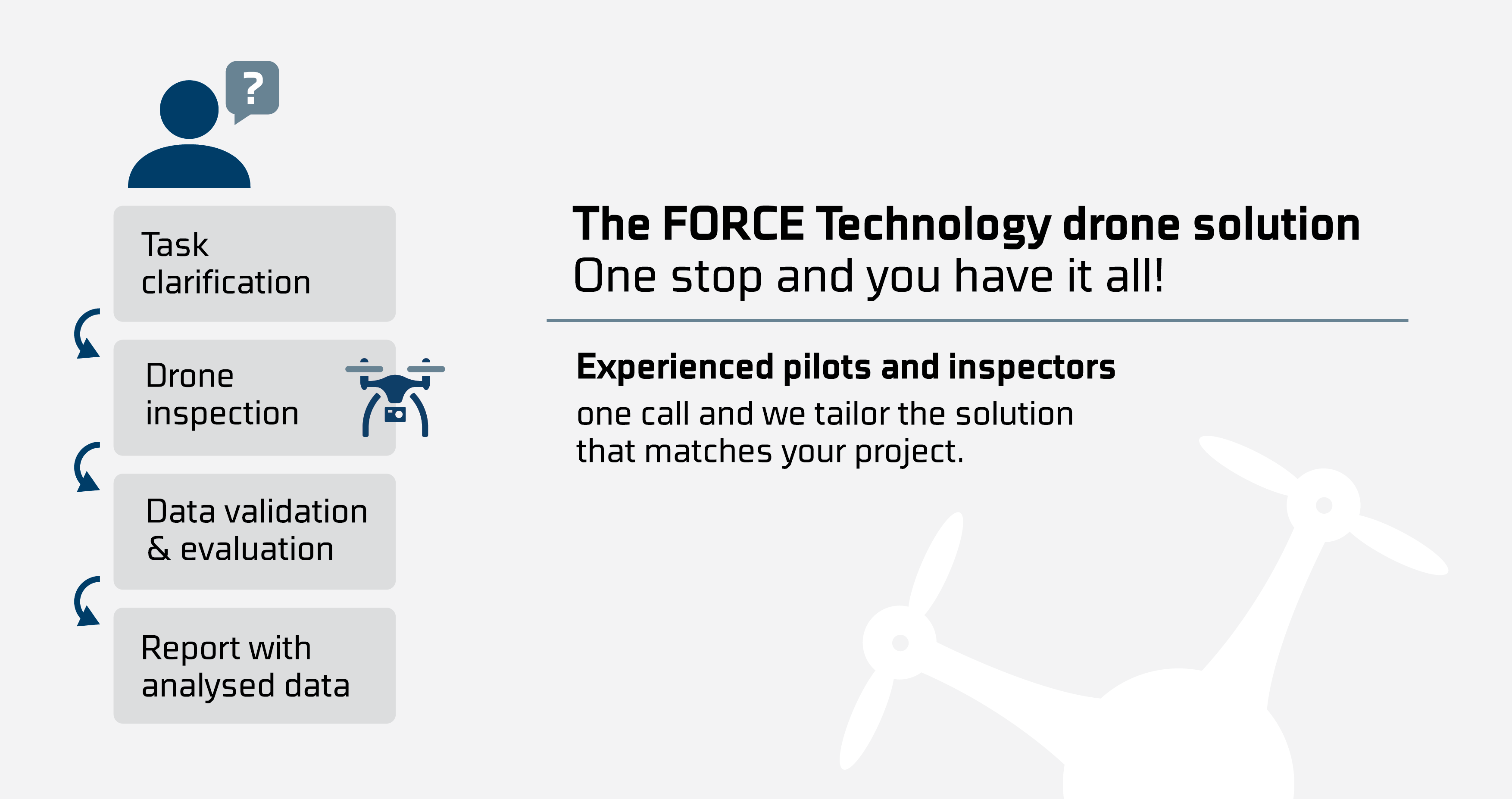

The FORCE Technology drone solution

Visual inspection by an unmanned drone is a quick and cost-conscious inspection method for onshore and offshore constructions i.e. tanks, wind turbines, chimneys, bridges and other hard to reach installations. Drone inspection enables access to otherwise inaccessible structures and details, offering immediate action as an alternative to more traditional, time consuming and costly inspection methods like helicopter, rope access, sky-lifts, cherry pickers and scaffolding.

At FORCE Technology, we only use drones when it is the optimal solution. Based on our extensive experience with and knowledge of all types of inspection, we always offer the best solution, tailor made for the job – with or without a drone.

Only experts ought to analyse data

During the aerial inspection, a FORCE Technology pilot operates the drone. During the flight, our certified NDT personnel usually operate the camera, record video and direct the pilot to the points of special interest and views of different angles of the construction.Under normal circumstances, the drone inspection itself is quickly finished. The heavy workload lies in the analysis of the collected data, and the pictures taken by the drones. It is essential here to enlist relevant experts in analysis to obtain the full value from a drone inspection.

Someone lacking the necessary qualified experience may overlook a critical defect or fault, possibly with fatal consequences. For instance, an inspection concerning a steel construction requires an expert metallurgist to analyse and interpret the data.

An inspection report is produced, based on the analysis of this data, and is usually divided into categories of red, yellow and green priority according to the seriousness of the damage. This report can if needed include a service plan with recommendations to cost-effective improvements.