Inspection of concrete in wind turbine foundations

Be assured that the concrete in your foundations for onshore or offshore wind turbines can withstand the enormous loads from the wind turbines, even under extreme environmental conditions.

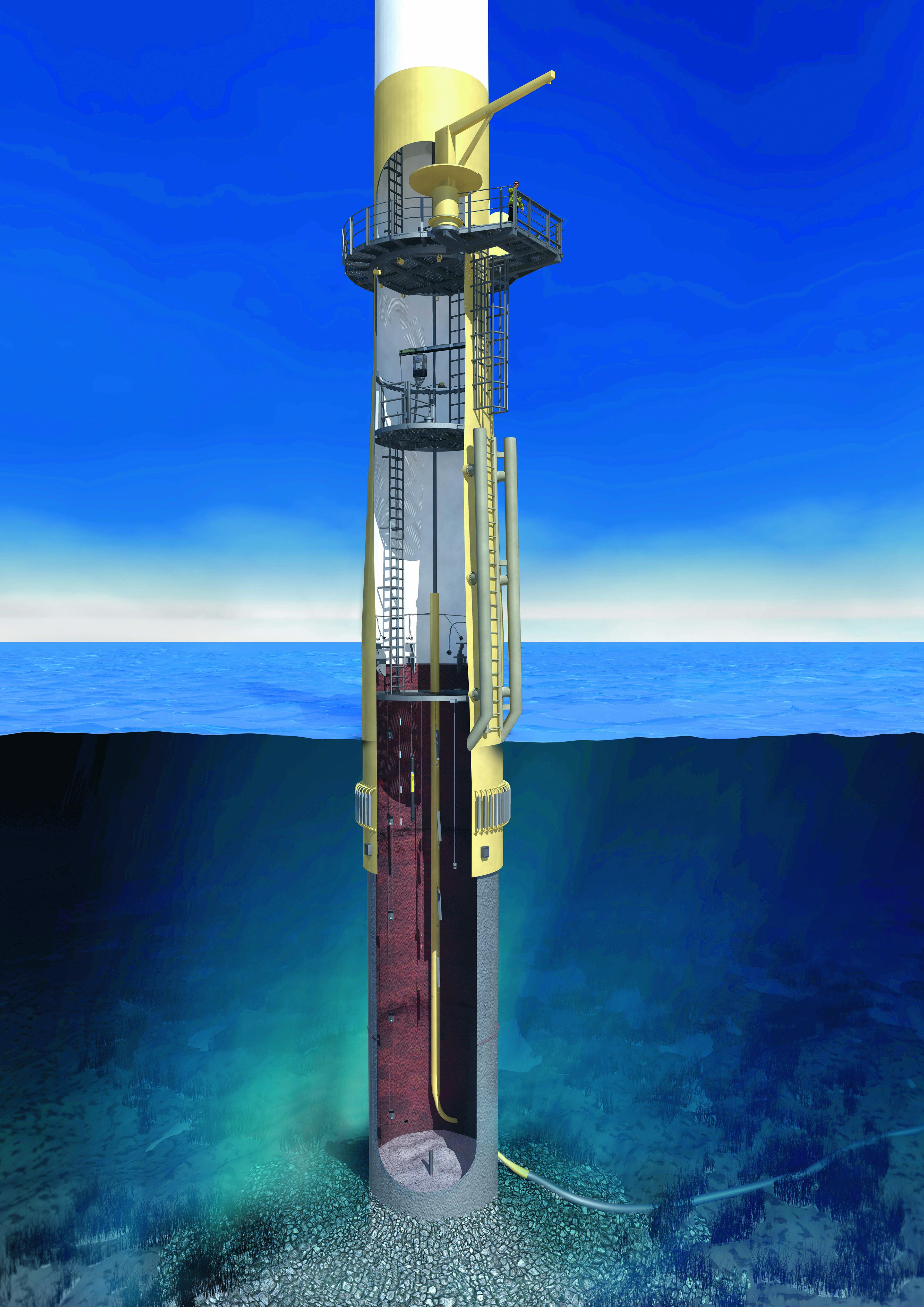

The significance of the foundation to the service life of wind turbines

Onshore wind turbine foundations are massive structures. The foundation must form solid anchoring for the steel anchors that connect the tower to the foundation. If a foundation fails, it may have serious consequences for the remaining service life of a wind turbine and entail a considerable loss on operations.

The extreme environment offshore is challenging for the materials of the foundations and possible material failures may have enormous financial consequences.

Concrete is increasingly used in production of wind turbine towers. Wind turbine towers must withstand enormous loads, which are transferred from nacelle to tower and further down to the foundation. To enable this, it is necessary to use high strength concrete combined with both traditional and posttensioned reinforcement.

This combination presents increased requirements for the materials used in the construction and also the workmanship. Both require control and documentation.

Get detailed knowledge about your structure without damaging it

The economic consequence of failure of foundation or tower is very serious. Therefore prevention of unexpected failures requires control and testing both during construction and operation.

By applying non-destructive examination methods you get detailed knowledge about the condition of the structure without damaging it. Vital data from a large area can be registered quickly and give a detailed view of the state of the structure.

You may for instance use this information to minimise the number of destructive testing, which is often used for core drilling to determine concrete strength or for breaking up, where you would like to know the extent of reinforcement corrosion. Further to this general view, you achieve cost savings - not only financially, but also in terms of time, compared to an increased number of breaking up resulting in subsequent repair.