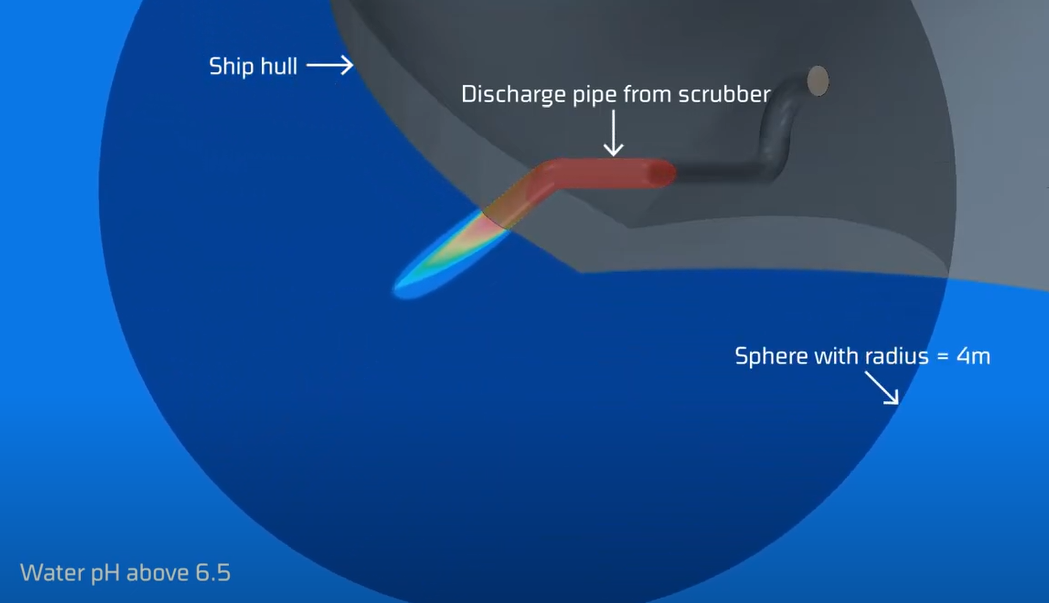

pH simulation of marine scrubber discharge

We offer a quick and flexible model to document compliance with the marine scrubber discharge regulations, with several hundred ships approved by all major classification societies.

New marine emission regulations from 2020

As of 1 January 2020, IMO has set a global limit for sulphur of 0.5% in marine fuel used on board ships to reduce the amount of sulphur oxide (SOX) emitted from ships. To meet the SOX emission requirements, ships may either use fuel with less sulphur or use approved methods for flue gas cleaning.

This could be exhaust gas cleaning systems also known as scrubbers, which clean out the emissions before releasing the exhaust gas to the atmosphere. The scrubber suppliers or shipping company must document that the wash water discharge does not harm the marine environment.

Combination of fluid mechanics and chemical models

According to MEPC, the discharge wastewater must have a pH value of no less than pH 6.5 at 4 m from the overboard discharge point of the ship. To document compliance we have developed a CFD model (computational fluid dynamics) that simulates the pH value in the seawater in a 4 m radius from the wastewater discharge.

Fluid mechanics and chemical models are combined and included in the CFD model. This gives a clear indication, if the scrubber unit can in fact discharge wastewater with lower pH than expected because of the mixing of the seawater around the discharge hole. Hereby the lowest possible pH value for discharge water is found. This can result in a decreased OPEX for the scrubber system.

Approved by all major classification societies

The methods used in the CFD model and its documentation have already been approved by all major classification societies for documentation of compliance with MEPC.259(68).

Communication with the classification societies is key. Once the report has been submitted for approval, our service includes a follow up on any comments from the classification society.

Access to hull geometry database

We hold many years of experience in the maritime business and we have access to databases, with a vast variety of hull geometries.

Insert optimisation

For situations where compliance is challenging to attain, the model can help to design and optimise an insert to improve the mixing between wastewater and seawater. We have conducted a study where more than 35 different insert designs were tested and compared in terms of mixing efficiency and pressure drop.

We concluded that a simple design, allowing an easy installation, was the best option. However, for each particular case, the insert can be optimised to obtain compliancy at a certain pressure drop.

Visual presentation of CFD results

With the CFD model the results are presented visually and it gives a fast and clear picture of the obtained results and how to comply with the regulations. It is a powerful tool when communicating with the classification companies and getting to know the details of discharge conditions.

Quick and flexible model

The method of using CFD simulation offers a quick solution, suited for the specific discharge layout. The report may be used as documentation in communicating with the classification companies in preparation for an approval of the scrubber unit design and discharge.

Facility

Flow laboratory

Services

Measurements for structures and machinery

Measurements of loads, deformations, strains and vibrations, for general purpose and projects.

Airborne emissions, incl. odour and micropollutants

Emission measurements ensure compliance with regulatory requirements for measuring.

Environmental rules and regulations

Consulting for all types of companies on environmental legislation.

Design and validation of flue gas cleaning systems

CFD design and assessment to assert environmental regulation compliance.