We help define 3D printing technology standards

Industry 4.0 comes with new forms of production, including 3D printing and Additive Manufacturing, which open up entirely new ways of working with materials. But how will quality control look with the new production techniques? FORCE Technology helps define new directions in quality control.

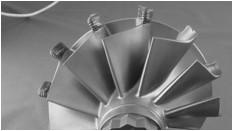

It is already possible to 3D-print using everything from plastic and composites to metal and concrete. 3D printing and additive manufacturing (AM) have also found their way into medical implants, eyeglasses and even the aerospace industry.

The advantages of AM technology are that products can be designed free from the limitations of traditional manufacturing, that you can quickly produce prototypes, that you can incorporate functional details within the structure and achieve very big time savings.

A company on the cutting edge will lead the market.

FORCE Technology has a high level of expertise in additive manufacturing and more than 20 years of experience with special laser cladding technology. For FORCE Technology, it is important to follow the market trends and keep track of where the technology is headed.“We make sure that we continue to build our knowledge in the AM field so that we can be a safety net for companies when they face challenges with the new 3D printing technology. We need to be ahead of the market so we can provide the best advice and help companies to exercise due care,” says Michel Honoré, specialist in 3D printing and AM technology at FORCE Technology.

The components behave differently

Additive manufacturing differs from traditional production methods in that the technology builds up the workpiece by a layer on layer process. As a result, the printed components can face challenges with porosity, embedded particles and delamination (i.e., the printed layers can potentially separate from each other). This means that there must be a different kind of quality control of the finished product than is used in a traditional production process.“The most important parameters to check, of course, are the ones that determine the subject's 'fitness for purpose'. It can often be something as simple as the geometric tolerances that are not automatically turning out as originally conceived and designed,” says Michel Honoré.

Influence the new standards

The introduction of AM technology demands new standards to ensure the quality of a 3D printed component. At present, international work is being done extensively in this area: 13 standards have already been published and around 50 new ones are on the way.The new standards set quality requirements both for the finished component, for the 3D printer equipment and for the people who operate the 3D printers.

“The new technology needs the same standardisation foundation that is well-known from traditional manufacturing methods, but since the AM processes are essentially different from traditional methods, the standards apparatus must be built from the ground up and include everything from production, equipment, training and education and test methods for HSE so that the foundation for 3D printing and AM is as strong as for traditional manufacturing," says Michel Honoré, who is actively involved in the standardisation work.

He is a member of the Danish Standard S858 Committee and in the international standardisation group TC261, where he is the Danish representative. Here he helps develop new test methods for quality control of AM processes and he is a contributor of important knowledge about testing and interpretation of test results.

“We participate in the standardisation work to keep our finger on the pulse of the field and to keep track of what is going on in all aspects of standardisation in the AM field, both on the manufacturing side and in the subsequent testing and characterisation. Our contribution is knowledge of AM and years of experience from traditional industry, where we know the requirements and methods that the industry is already tending toward.”

Acquisition of important knowledge

Active involvement in the standardisation work within this new technology field also means that FORCE Technology's employees are up to date on important knowledge about the development of the latest standards.“The knowledge we gain from standardisation work is something we can pass on to our customers and apply in our daily work with AM and 3D printing. In addition, we draw on this knowledge in our daily consultant work with companies and we make sure that the new standards are taken into account at an early stage in the companies' product development processes,” says Michel Honoré.

AM versus 3D – what are the differences and similarities?

3D printing is a specific kind of AM that is done in a 3D printer, which prints the items directly from a computer model, very similar to what you know from traditional printing. Most often the material has been plastic, but in recent years it has become possible to 3D print in various metals and even in concrete.