3D print - test, consultancy and printing

If you want to be sure that your 3D-printed components live up to and meet your requirements, FORCE Technology offers tests, advice and printing in a single one-stop-shop.

Whether your needs are for a specific component to be 3D printed, its performance to be verified or tested, or for optimization of a 3D printed product, FORCE Technology offers relevant know-how and access to all the relevant technologies and equipment. Besides, we can help you quality assurance your 3D printed product items.

Build trust in 3D-printed items

Do you need to build confidence in the performance and quality of your 3D-printed components? Based on our knowledge in material technology, testing and quality assurance, we offer advice on relevant test methods for qualifying your 3D-printed products, both through advanced and simple inspection methods.

A part of the green transition?

3D printing is a production method that uses fewer resources than traditional methods. Moreover, items can be produced locally in Denmark, meaning that some companies can save on transportation from abroad.

If you choose the right materials, which take into account both the specific usage environment and the environmental impact, 3D-printed items can therefore ensure you a lower CO2 emission than alternative production forms. This can contribute to the green transition of your company.

However, the choice of material for 3D printing is always a balancing act between what is possible with 3D printing, the expected lifetime, and the material's environmental impact.

3D printing and testing in-house

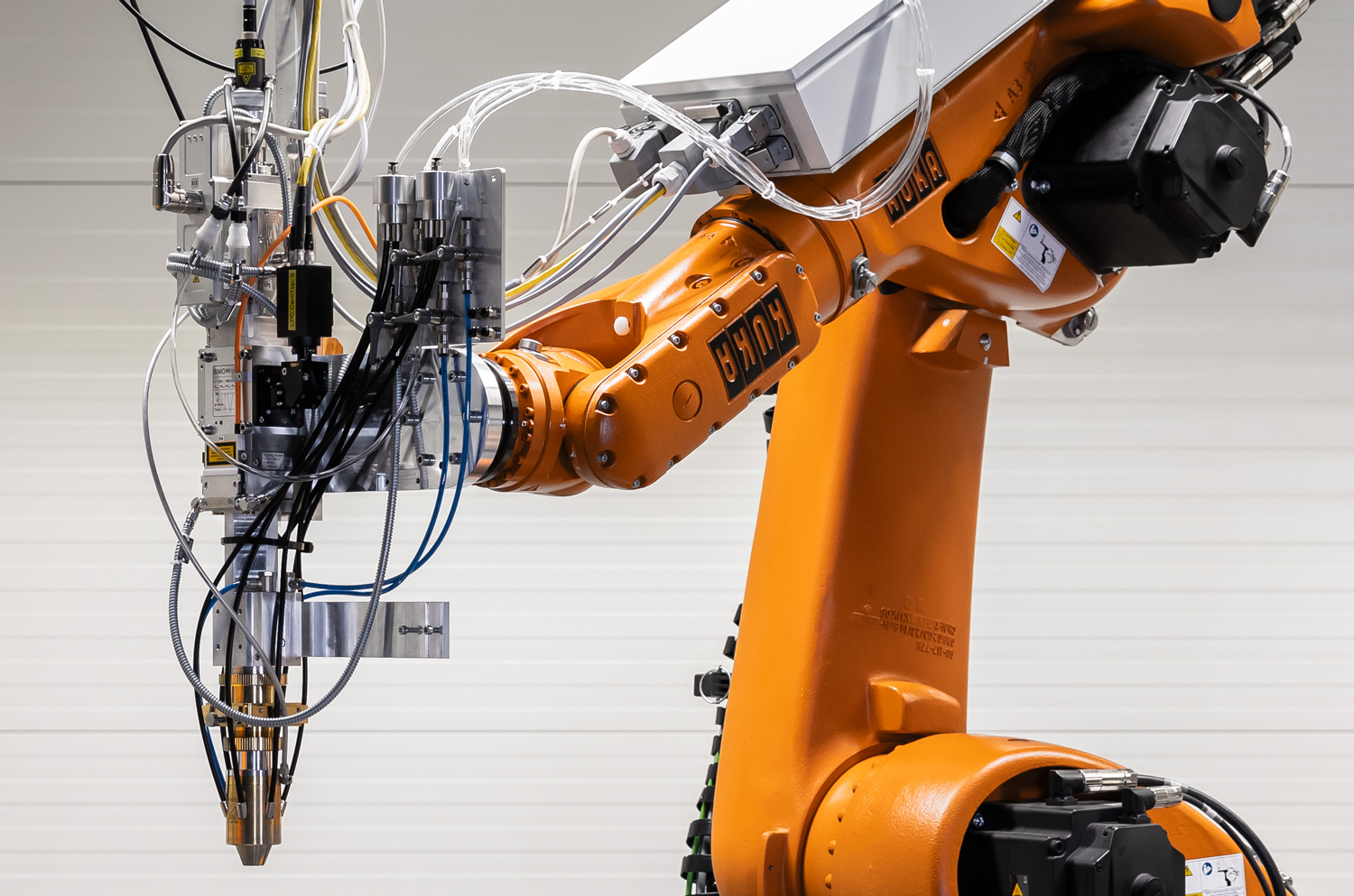

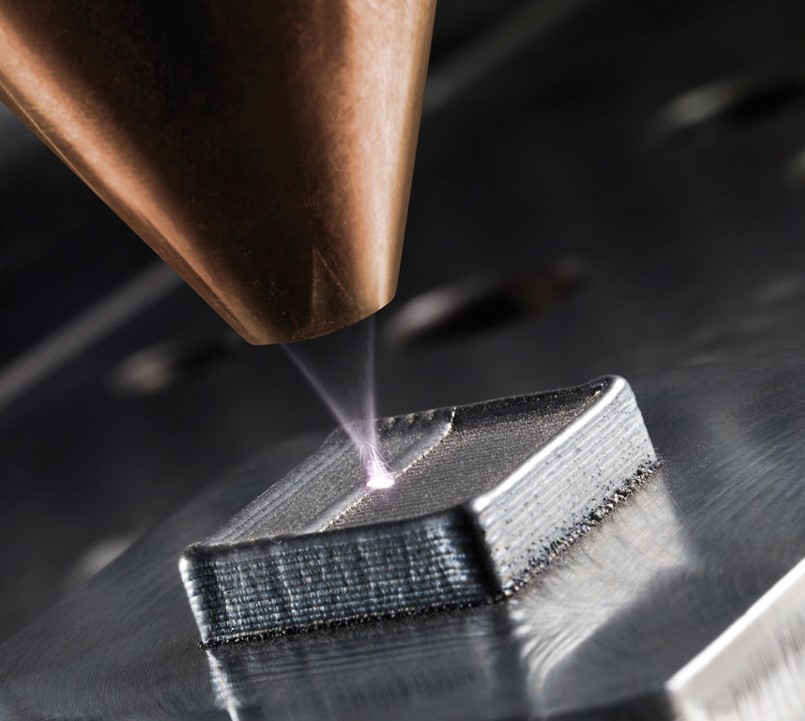

Building on our extensive knowledge in the fields of testing, materials technology and laser processing, FORCE Technology offers access to one of Northern Europe’s largest facilities for additive manufacturing. With our AM-facility we can:

- Print 5 meter long, 1 meter in diameter

- Handle items up to 3,000 kg

- Quickly manufacture prototypes or customer-specific geometries

- Repair or apply surfaces

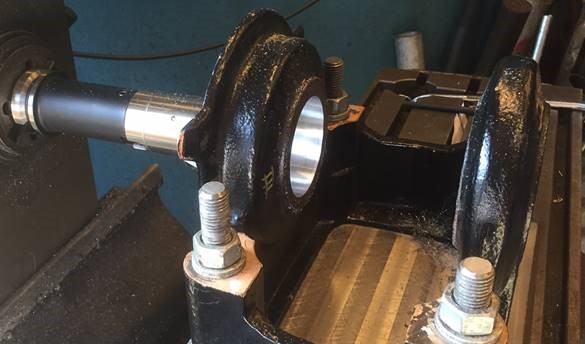

- Perform surface coatings inside pipes (ø80 mm to ø1000mm)

- Test, validate and quality assure AM / printed items

Larger items have a rough finish, short delivery time and the geometry you need.

We can qualify 3D-printed items, and test both non-destructive and destructive whether they meet the quality requirements. Our facilities include destructive and non-destructive testing facilities for the qualification of 3D-printed parts, including simple verification of dimensions, methods for identifying any defects and verification of material properties such as mechanical properties and fatigue.

Implementing 3D print in production

With 3D print stepping out of the shadows of prototyping and entering production, you may find that you miss know-how on quality assurance or a need to adhere to specific, relevant industry standards.

FORCE Technology partake in national and international standardization work within the field of standardization of 3D print and AM, in all relevant aspects from production to quality assurance, HSE and training of operators for 3D print. The know-how gained from these activities is put to play in our advisory services to the industry, allowing for an early implementation into the production strategy.

Case

The architects from BIG use 3D metal printing

Article

AM versus CNC machining

Article