Advanced X-ray and neutron analysis

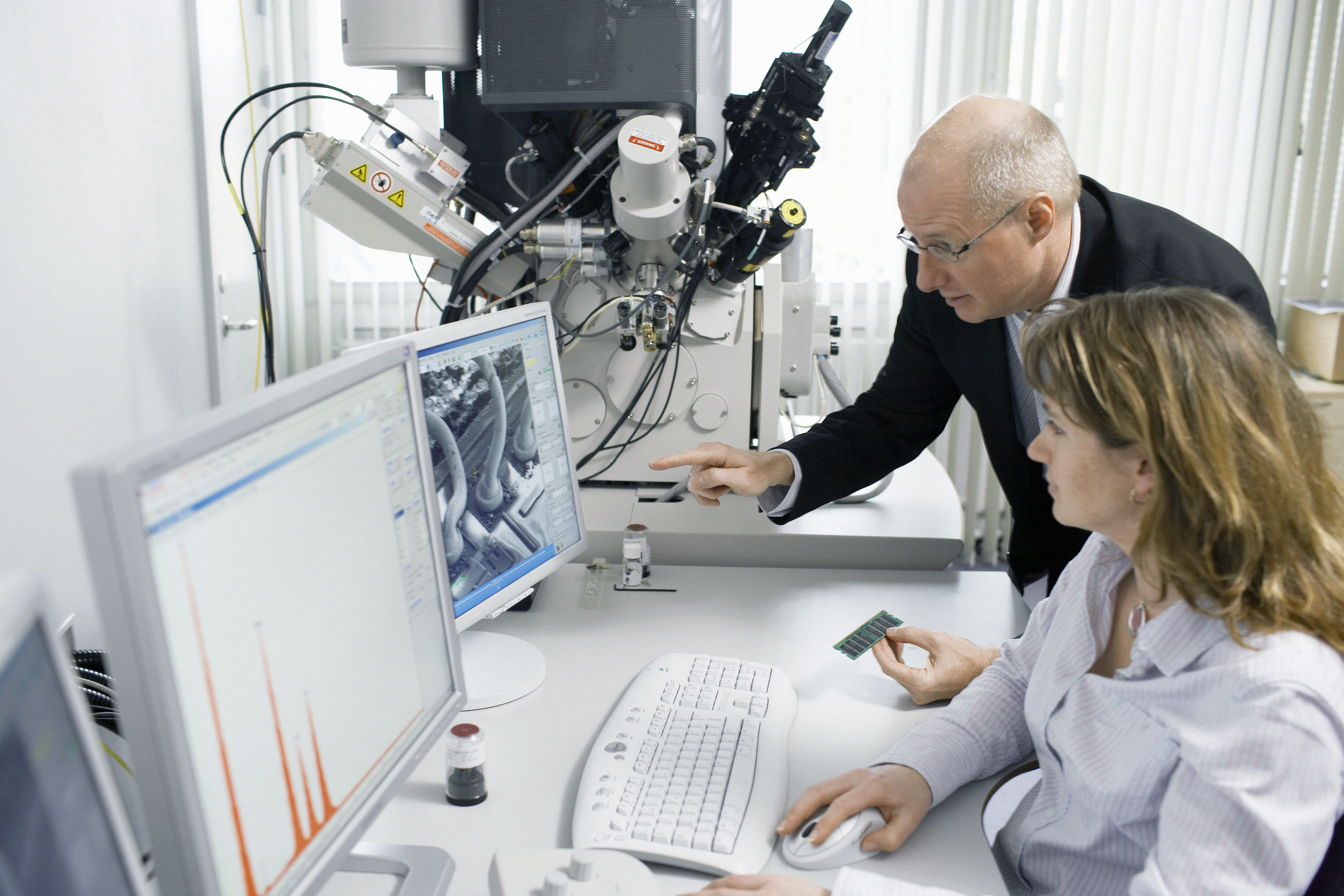

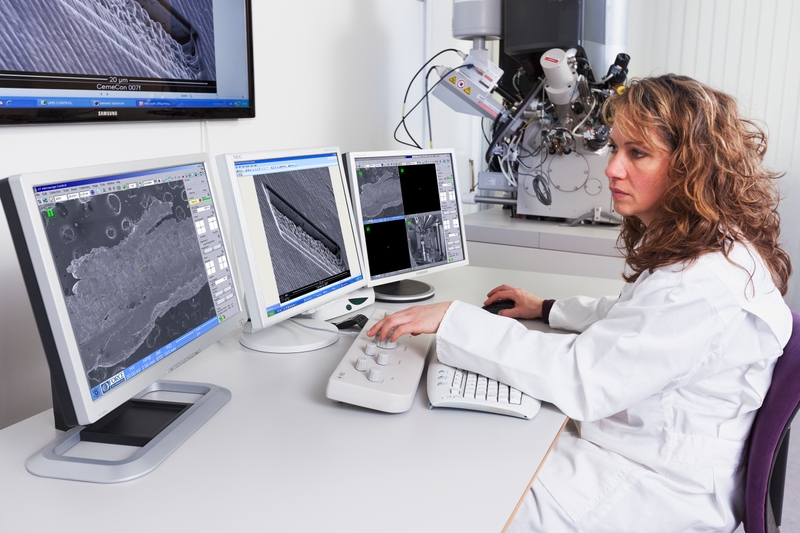

Get access to the most advanced X-ray and neutron characterisation methods. This includes analysis using tomography, small angle scattering, XRD, chemical composition and many more.

X-ray and neutron technologies are complementary and can be used to study various kinds of materials and properties in materials.

We have access to several advanced x-ray and neutron characterisation facilities. This also includes advanced equipment at Danish and international research facilities.

On top of that, we have built deep technical skill sets and a mediator structure that enables us to solve your challenges using results from these advanced facilities.

Long list of methods for X-ray and neutron analysis

Some of the characterisation methods you can benefit from are:

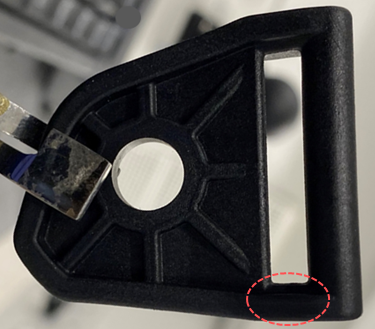

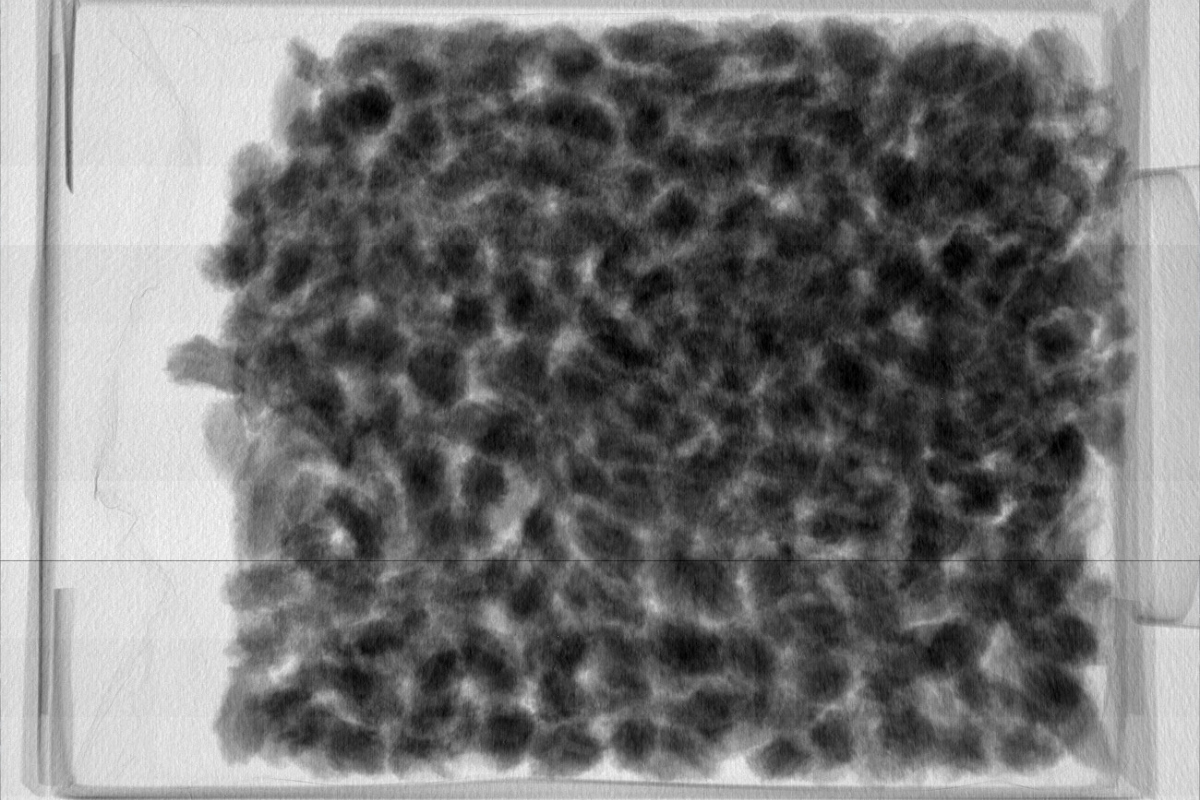

- Tomography (3D x-ray CT, neutron CT)

- Non-destructive 3D imaging of samples in sizes 1-500 mm, with a resolution down to 250 nm. Samples in polymers, steel, and aerospace materials.

- Small angle X-ray/neutron scattering (SAXS, SANS)

- Probe structures 1-100 nm.

- Powder X-ray Diffraction (XRD)

- Phase identification of crystalline materials, average bulk composition, unit cell dimensions.

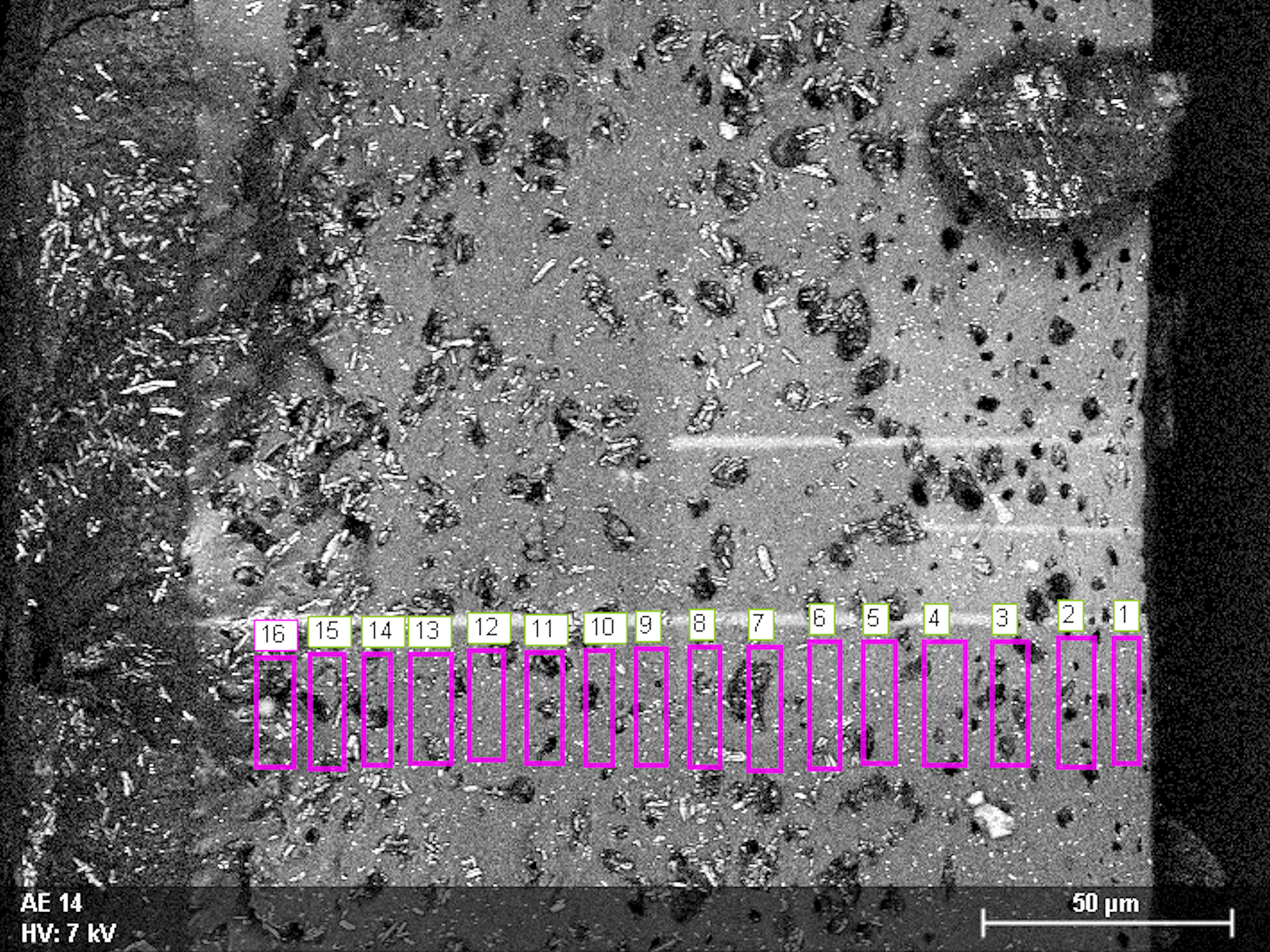

- Chemical composition (XRF, EDS, XPS, XANES, EXAFS)

- Methods to probe elemental and chemical composition, including binding state of the different elements.

- Trace element analysis (PGAA)

- Detection of PPM and PPB trace elements in materials – including hydrogen.

- Fibre orientations in e.g. FRP plastics (DDF, SAXS, CT)

- Mapping of local fibre orientations inside materials.

And the list of characterisation methods goes on …

Do you need other advanced characterisation methods than the ones listed above?

We have experience in identifying where other methods are commercially available, and in providing access to them. So get in touch, and we will be happy to help you out.

Advanced analysis for your industry

Industries that have benefitted from our characterisation services so far include:

- Pharmaceutical industry

- Medical devices

- Power-to-X

- Space and aerospace industry

- Wind turbine industry

- Food and packaging industry

- Oil and gas industry

- Shipping industry

- Plastics industry

Article

Neutrons can see things that are impossible to see

Article

Quality control of 3D printed metal using 3D X-ray CT

Article

Antifouling coatings for ship hulls

Article

3D X-ray CT scanning for injection moulding

Article